Cement production is associated with high energy consumption. Therefore, it makes ecological and economic sense to intensively search for less energetically demanding synthesis routes.

Chemical composition, crystal phases and structures on the length scale of a few nanometers are essential parameters of the calcium silicate phases in cement, which are influenced by parameters in the process control. A quantitative analysis of the nanostructure is usually carried out using a DIN method, namely N2 adsorption analysis. Here, detailed analyses take 12 to 24 hours; an accelerated analysis process with lower information density usually requires several hours including sample preparation. N2 adsorption analysis thus represents a bottleneck in material development or process and quality control.

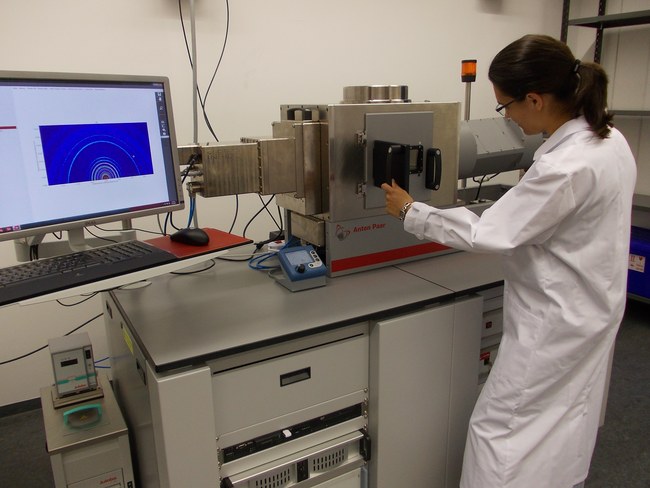

With the expertise of ZAE Bayern in Würzburg, Schwenk Zement KG has now succeeded in establishing a tool in cement analysis that was previously reserved mainly for basic research. We are talking about so-called small angle X-ray scattering, or SAXS for short. The method is comparable to the scattering of a laser beam when passing through a glass pane with a roughened surface: the widening of the beam by scattering is characteristic of the surface roughness of the pane. The situation is similar for small-angle X-ray scattering: since the "test scale" in SAXS is less than 1/100 of the wavelength of visible light, the method is particularly sensitive to nanostructures in the range of about 0.1-100 nm.

The scattering signal detected by a detector in SAXS provides the structural fingerprint of the cement phases within minutes. The data can be used to determine, among other things, the specific inner surface area of the cement powders. In close cooperation between Schwenk Zement and ZAE Bayern, this parameter determined from SAXS was validated by means of comparative measurements with N2 adsorption analysis. ZAE Bayern and Schwenk Zement KG were thus able to establish the SAXS method as a characterization method for the cement industry.

Schwenk Zement KG can now use the method to advance material development more rapidly. In addition, the rapid method also lends itself to quality control in production. After the first systematic preliminary tests at ZAE Bayern in Würzburg, Mr. Neumann (Schwenk Zement KG) enthusiastically states: "I had hoped that the analysis method would help us, but I had not expected it to work so well". At Schwenk Zement KG, samples are already taken from production at short intervals and examined automatically by an analysis robot. Until now, it has not been possible to determine the specific surface area at the same rapid rate as other parameters. This will change in the future with the support of ZAE Bayern through the fast SAXS method.

(Source: ZAE Bayern)

![[Translate to English:]](/fileadmin/_processed_/f/0/csm_logodgm-4_b2722eeace.png)

![[Translate to English:]](/fileadmin/user_upload/logodgm-4.png)