Workshop: Programable materials in application - potentials and hurdles

Wednesday, 24 September 2025

Time:

1:20 PM

Duration:

2.5 hours

Moderators:

Prof. Dr. Chris Eberl (Fraunhofer Institute for Mechanics of Materials IWM)

Dr. Jochen Barth (Fraunhofer Institute for Machine Tools and Forming Technology)

Innovating with NextGen Materials: From Research to Industry Applications

- Introduction to programmable materials and the implementation in industrial products

- Interactive discussion on possible fields of applications

- Sharing experience from development processes with NextGen materials

- Drawing conclusions on how to tackle challenges and obstacles

Global challenges such as sustainable development, climate change, renewable energy, or individual mobility increase the necessity for a much more efficient and sustainable use of our resources.

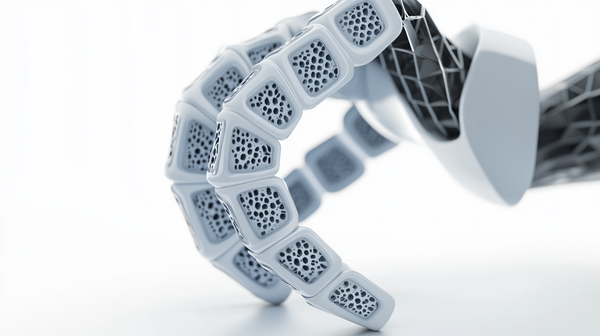

Programmable materials have the potential to initiate a paradigm shift since they can perform system functions through their internal design. This allows for increased functional integration while simultaneously reducing system complexity. Programmable materials are materials whose inner structure is designed and manufactured in such a way that properties and behavior can be controlled and reversibly changed. Furthermore, locally varying functions can be programmed into such materials.

Fully functional programmable materials require a combination of smart materials, mechanical and optical meta materials, the ability to manufacture architectured materials through e.g. additive manufacturing or sheet metal forming. Last but not least a highly interactive, interdisciplinary application design route is necessary to exploit the full potential.

This opens up possibilities for novel application solutions where essential parts of system functionality are provided by the material itself. The programming ability stems from build in logical elements (e.g. if T > 380 K then E = 10 GPa else E = 1 GPa, with E being the Young’s modulus), materials memory (e.g. bistable mechanical or molecular states) and the ability to process functions (e.g. Poisson number as a function of strain in x-direction: ν = f (εx)). The material response can either be triggered externally or the materials can automatically adapt to changing conditions in a predetermined manner.

The application potential for programmable materials is immense: programmable pore sizes enable self-cleaning membrane filters for water treatment systems, materials with programmable heat transfer ensure energy-efficient heat management in machines or buildings, shape morphing materials can change aerodynamics and programmable friction can be used to intelligently control coupling and positioning systems.

Programmable materials have the potential to initiate a paradigm shift in the design and use of materials by replacing technical systems of many components and materials with a single, locally configured one. The key to this is the programmable design of the internal structure.

Thematic priorities can be: the simulation of programmed materials, the optimization and programming of material functions, the development of suitable process technology for modular or hybrid production of programmable materials or the validation of programmable materials by demonstrators and prototypes. Also challenges from industry partners that could be addressed by programmable materials are highly appreciated in this symposium.

NextGen Materials 2025

23 - 25 September 2025 | NextGen Materials in Hamburg (Germany) & online

NextGen Materials 2025

23 - 25 September 2025 | NextGen Materials in Hamburg (Germany) & online

Sign up for our newsletter

Subscribe to our newsletter for regular updates about materials science topics!

After subscribing, you will receive an email from us with a confirmation

link.

Only after clicking this link your registration is completed.