Component Metallography is a method for assessing the current and damage condition of components before and after operational stress. This allows for microstructure determination and surface examinations with minimal destruction. The preparation is carried out through grinding, polishing, and etching using portable devices directly on the component. The microstructure and damage condition are captured on-site using a magnifying microscope or through impression techniques.

The significant advantages of Component Metallography lie in its nearly unrestricted applicability, the rapid availability of examination results on-site, and the cost-effectiveness of the method. However, achieving flawless test results requires specific work and procedural techniques, as well as craftsmanship in preparation, impression techniques, and evaluation.

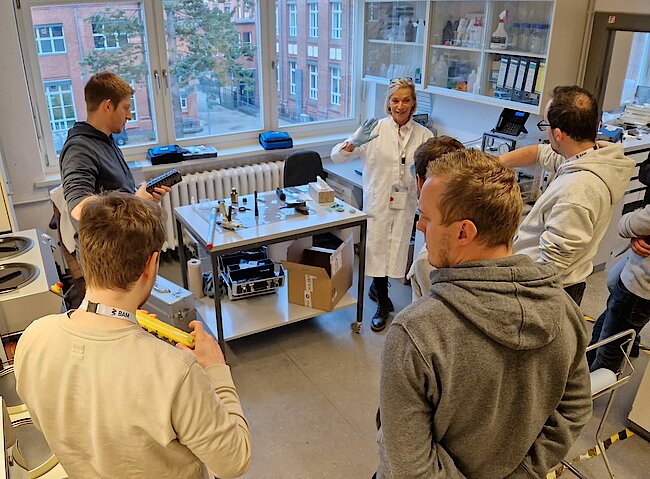

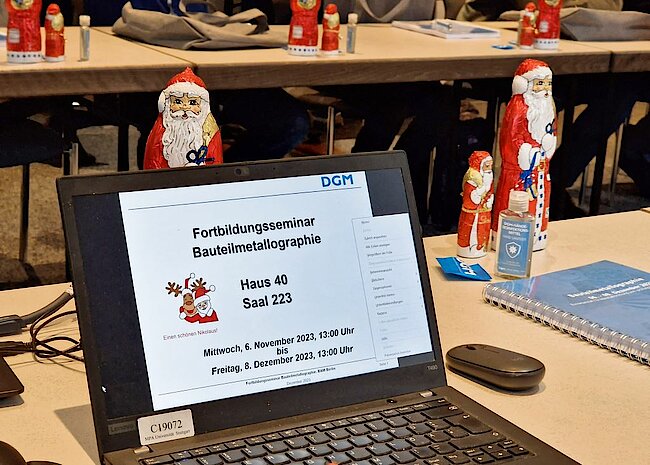

The training course thus offered a broad spectrum of topics and content, allowing participants to gain comprehensive insights into the possibilities of Component Metallography and deepen their theoretical knowledge through practical exercises. This enabled them to learn and practice each step, from preparation to evaluation, within typical application scenarios.

The training course also included a networking evening with a shared dinner. This provided participants with an ideal opportunity to further exchange their experiences and deepen their understanding of the training content in a pleasant setting.

A heartfelt thank you to all participants and especially to the training leaders, Rudi Scheck and Prof. Dr.-Ing. Magdalena Speicher.

The next training course on this topic will take place next year from 4 to 6 December 2024 – seize the opportunity to benefit from the knowledge gained and explore the fascinating world of Component Metallography together with Rudi Scheck and Prof. Dr.-Ing. Magdalena Speicher!

![[Translate to English:]](/fileadmin/_processed_/f/0/csm_logodgm-4_b2722eeace.png)

![[Translate to English:]](/fileadmin/user_upload/logodgm-4.png)